Guest Post: Alice & Lois Tours Rit HQ

This post is in partnership with our good friends Alice & Lois!

Color is a pretty magical thing. Being able to give new life to something that has been cast away is like magic. I was lucky enough to get to visit the Rit Dye plant in Indianapolis last month. The dyes have been made in Indianapolis since 1948 (started in Chicago in 1918). The plant has the bottling line, a huge space where the dye is actually made, a lab and office space. I just love our Indy connection. We love doing DIY projects with dye, so this was amazing to see how and where the dye is made.

There were about 8 – 10 employees running the show the day of my visit and they were bottling their new Eggplant dye.

My tour started with visiting the actual room where the dye is mixed. Huge stainless steel vats are essentially the massive mixing containers where the dye is created. The dye runs from the massive vats into the bottling lines.

The start of the line is where the empty bottles are loaded. Then they move through to get sorted and put in the proper position. They get filled with dye and capped. Then they get wrapped in the packaging. There are checkers along the way to make sure every bottle is perfect. The bottles continue down the line and get inspected and then boxed.

It is a truly amazing process to watch. On average, the plant produces about 48,000 bottles and 144,000 powder boxes per day! And those bottles travel all over the world, giving people like us the opportunity to create something beautiful.

The lab area is what you would think of a university lab. Beakers, machines, bottles, timers, tools and more! I was so fascinated by it all. It was so cool to think about the science behind all of the dyes. To be in the lab, and then go into the massive dye vat room (where they actually make huge vats of dye to go into the bottling process) was incredible.

The articulate bottling line would not exist without the passionate employees. I got to chat with a few of the employees about working at Rit – Peggy, Kathy, Allie and John to name a few.

Kathy has been part of the Rit Dye family for 22 years. She has done multiple jobs within the organization. She was a purchasing agent, purchasing director and now VP of Operations. She oversees the plant and purchasing and operations for the brand. She is an inspiring leader. “I love different things everyday, always something new to learn and deal with,” she says. Kathy also prides herself on never shorting an order, no matter the size!

The last person to triple check the orders before they go out the door is Peggy. She has been with Rit Dye for 33 years when a friend recruited her. She has done every single job at the plant except for mixing. “I look at our dye when I am in the store, make sure it looks good and fix the labels” she said. She lit up when telling stories about bringing pictures of kittens to work and even a few co-workers adopting a few of her kittens. Now everytime I see Rit Dye on the store shelf I will know that Peggy checked to make sure the right order was sent to that store.

Customers not only have questions for the customer service team, but they share ideas for dyes and colors as well. The customer service email is always full with all kinds of questions from customers. Allie (Quality & Development Lab Manager) is busy answering those inquiries – from socks to lingerie to grout. She helps customers determine which dye to use and if in fact the item they want to dye is dyeable.

She said that Halloween is a very busy time for them. Weddings also seem to be a popular topic from customers as well. If someone wants to dye invites to match the bridesmaids’ dresses or dye a ribbon for decorations. Allie will take care of them.

Behind the scenes at Rit is John, the “Dye Doctor”. The color match process is truly like a chemistry experiment. He told me story after story of how he helps customers find the perfect match using combinations of Rit Dye colors. He is essentially the color recipe developer for the brand.

How does the color match process work?

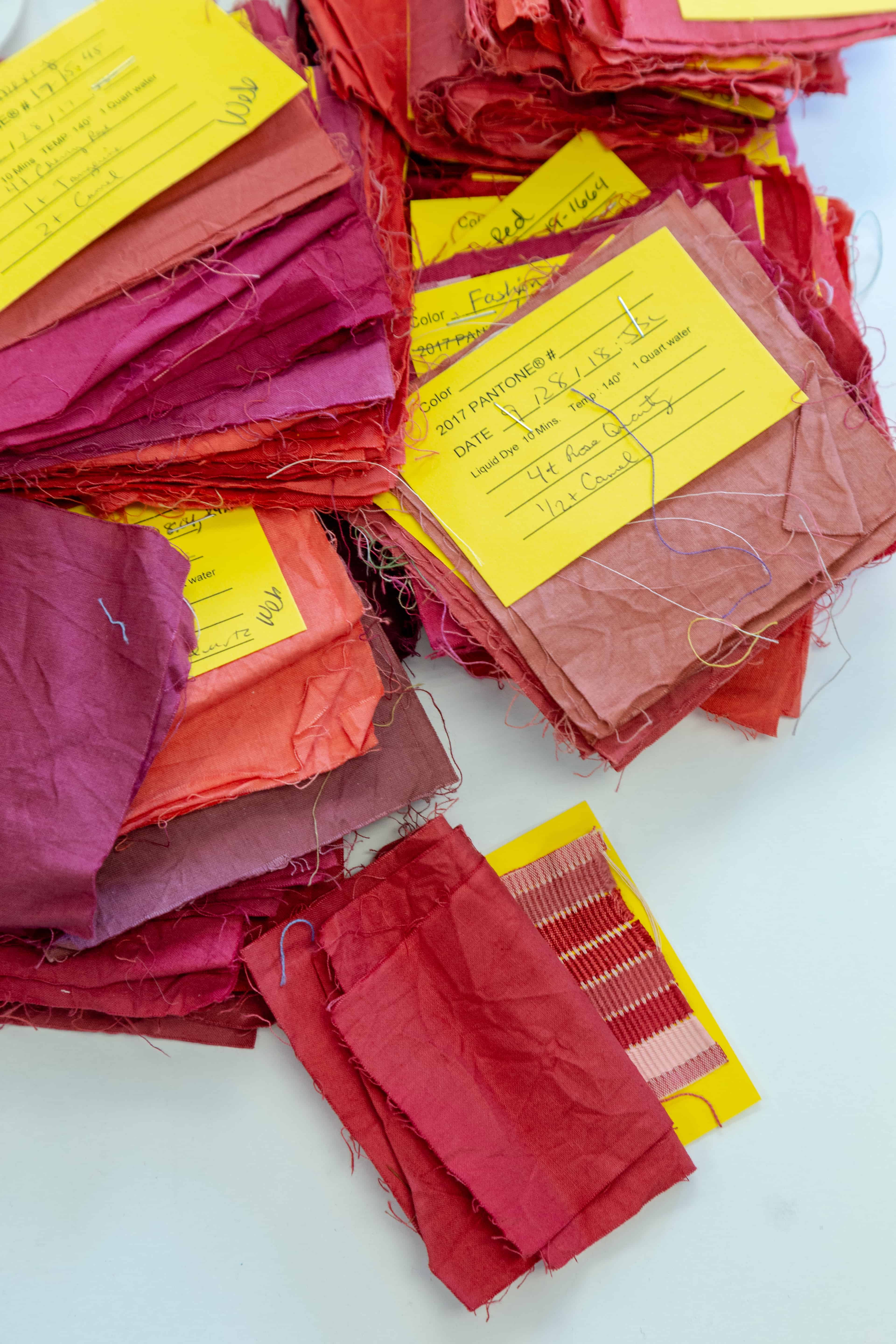

It is best when a customer sends him a picture or an actual Pantone number. He then looks through the 1,500 color formulas to see if he has a match. He has fabric swatches for thousands of color formulas. If he doesn’t see a match, he will develop some recipes to find one.

I got to experience this first hand on my visit. I had an old tablecloth and a few dishes of my grandmother’s. I had been dreaming up how to dye the tablecloth the same color as an accent shade in the plate. I knew John could help me find the perfect color match. We went through the swatches to see which tones and colors resembled the dark rose wine color in the pottery.

We then created four different recipes to find the best match. We mixed some colored dyes and dyed the swatched.

Alas, we found the perfect match.

John and Allie got a large stainless steel pot to a low boil. Added one cup of salt, a dash of liquid dish soap and the dye recipe and we were ready to go. The tablecloth was cotton, so we used a mixture of Rit All Purpose Dye.

I left the plant that day with a beautiful tablecloth that perfectly matched my nana’s dishes.

I cannot wait to bring the tablecloth to my mom and dad’s this summer and set a beautiful table with all of my Nana’s dishes. There is just something so special about revitalizing something old that will continue to hold so much meaning.